Red Sandstone Exterior Cladding NASA Johnson Space Center Building 21, Houston, TX Reminiscent of an Southwestern Desert skyline, Red Sandstone can be found all over the world in desert and dry areas. Colored by Iron oxide, Red Sandstone has a neutral warm red color. Red sandstone makes for great exterior cladding due to […]

StonePly Aluminum Honeycomb Reinforced Stone Panel Construction

How come StonePly aluminum honeycomb reinforced stone panels are so much stronger than un-reinforced stone slabs?

StonePly honeycomb reinforced stone panels have high impact strength, torsion and bending rigidity because of the aluminum honeycomb structure. The aluminum honeycomb core acts similar to an I-beam. The facings of honeycomb panels, aluminum on the backside and stone and aluminum on the front side, are similar to flanges of an I-beam, and the honeycomb core corresponds to the web. Unlike the I-beam however, the aluminum honeycomb core of the StonePly panel gives continuous support to the face. This structure is what gives many modern aircraft their performance capabilities. Aircraft with aluminum honeycomb cores endure relative wind speed changes of zero to 1,000 mph, intense vibrations, and temperature changes of +120 degrees to -30 below. No standard construction material could handle these stresses.

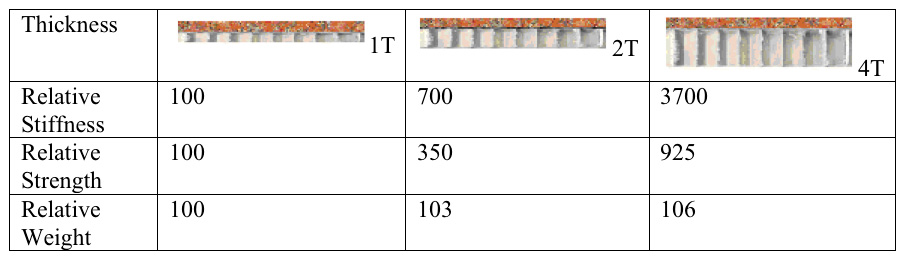

The chart below demonstrates the dramatic increase in strength the aluminum honeycomb core thickness provides without contributing appreciably to the weight.

About the strength:

- StonePly panels have passed the large missile impact test that shatters solid granite slabs

- StonePly has 60 X the impact strength of solid granite slabs

- StonePly attaches the stone to the aluminum honeycomb with aviation epoxies that provide a tested bond strength of over 43,000 lbs per sq. ft.

Comments are closed.