Red Sandstone Exterior Cladding NASA Johnson Space Center Building 21, Houston, TX Reminiscent of an Southwestern Desert skyline, Red Sandstone can be found all over the world in desert and dry areas. Colored by Iron oxide, Red Sandstone has a neutral warm red color. Red sandstone makes for great exterior cladding due to […]

StonePly Stone Panels: Testing for Aircraft Interiors

Testing StonePly: Lightweight natural stone for private jets and commercial aircraft interiors

About Stone Ply for Airplane Interiors

At first glance, stone on an airplane sounds like an extravagant idea. But consider this; StonePly weighs about the same as plywood, it’s non-combustible and beautiful. So thanks to the strength and lightweight properties of StonePly, airplane designers are able to use the exquisite beauty and quality of natural stone on private and corporate jets.

Designers, manufacturers and outfitters of custom airplane interiors for private and corporate jets have found StonePly to be a useful way to introduce the high end appeal of stone to their projects. StonePly offers a lightweight, strong and attractive real stone finish for airplane galleys, lavatories, flooring and tables. And in addition to the beauty and uniqueness of natural stone panels for aircraft interiors, StonePly also offers custom marble and granite insets, medallions and logos for use on airplane floors, tables and partitions.

Testing StonePly for Aircraft Interiors

The U.S. Department of Transportation Federal Aviation Administration (FAA) requires certain materials be fire tested. This following is a brief summary of Stone Ply’s test results and flame resistance abilities. For additional information on testing of aircraft materials, refer to the “Aircraft Materials Fire Test Handbook” for a description of all FAA-required fire test methods for aircraft materials.

Fire Resistance of StonePly Lightweight Stone Panel for Aircraft Interiors

StonePly offers designers of aircraft interiors a non flammable panel made up of a thin stone face bonded to a non flammable aluminum back panel with an aluminum honeycomb core. The materials are bonded together with a thin layer of high strength epoxy.

Airplane Interior Test: Vertical Bunsen Burner Test for Cabin and Cargo Compartment Materials

Result: Passed

StonePly meets or exceeds the requirements of the test. The tested StonePly aluminum honeycomb backed stone panels:

- Did not ignite

- Did not flame

- Did not drip

- Did not spread flame

Scope: This is a test for airplane interior finishes. This FAA test method is intended for use in determining the resistance of materials to flame when tested according to the 60-second and 12-second Vertical Bunsen Burner Tests specified in Federal Aviation Regulation (FAR) 25.853 and FAR 25.855.

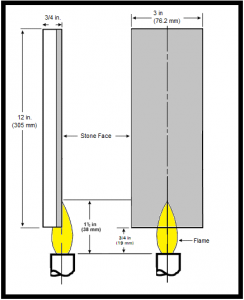

Samples were 3/4″ StonePly (1/4″ stone face and 1/2″ aluminum honeycomb), 2″ by 12″ samples. Both marble on aluminum honeycomb panels and granite on aluminum honeycomb panels were tested. The StonePly stone panels were exposed to the flame from a 3/8-inch Bunsen burner with a 1550°F minimum flame temperature for 60 seconds.

Result: No ignition, flaming, dripping or spread of flame.

StonePly Aluminum Honeycomb Stone Panel Testing: Vertical Bunsen Burner Test for Cabin and Cargo Compartment Materials

In the above test, the StonePly stone/aluminum honeycomb panel did not ignite, flame, drip or spread flame.

Airplane Interior Test: 45-Degree Bunsen Burner Test for Cargo Compartment Liners and Waste Stowage Compartment Materials

Result: Passed

This is a test for airplane interior finish materials used in cargo compartments. It is a similar test to the vertical test listed above, except for the angle of the panel. StonePly panels meet or exceeds the requirements of the 45- Degree Bunsen Burner Test. Both granite on aluminum honeycomb and marble on aluminum honeycomb panels were tested. When tested, StonePly:

- Did not burn

- Flame did not penetrate any of the specimens

- Glow time of less than 1.5 seconds was less than the 10 second standard to pass

Airplane Interior Test: Horizontal Bunsen Burner Test for Cabin, Cargo Compartment, and Miscellaneous Materials

This test method is intended for use in determining the resistance of materials to flame when tested according to the 15-second horizontal Bunsen burner tests specified in FAR 25.853. In this test, materials for airplane interiors are subjected to the flame of a Bunsen burner. StonePly granite on aluminum honeycomb and marble on aluminum honeycomb panels were tested.

Result: Passed.

Burn Rate – 0

- Did not ignite

- Did not flame

- Did not drip

- Did not spread flame

Conclusion

StonePly is safe for use in aircraft interiors.

If you have questions about attachments details or stone varieties available, contact StonePly.

No comments yet.